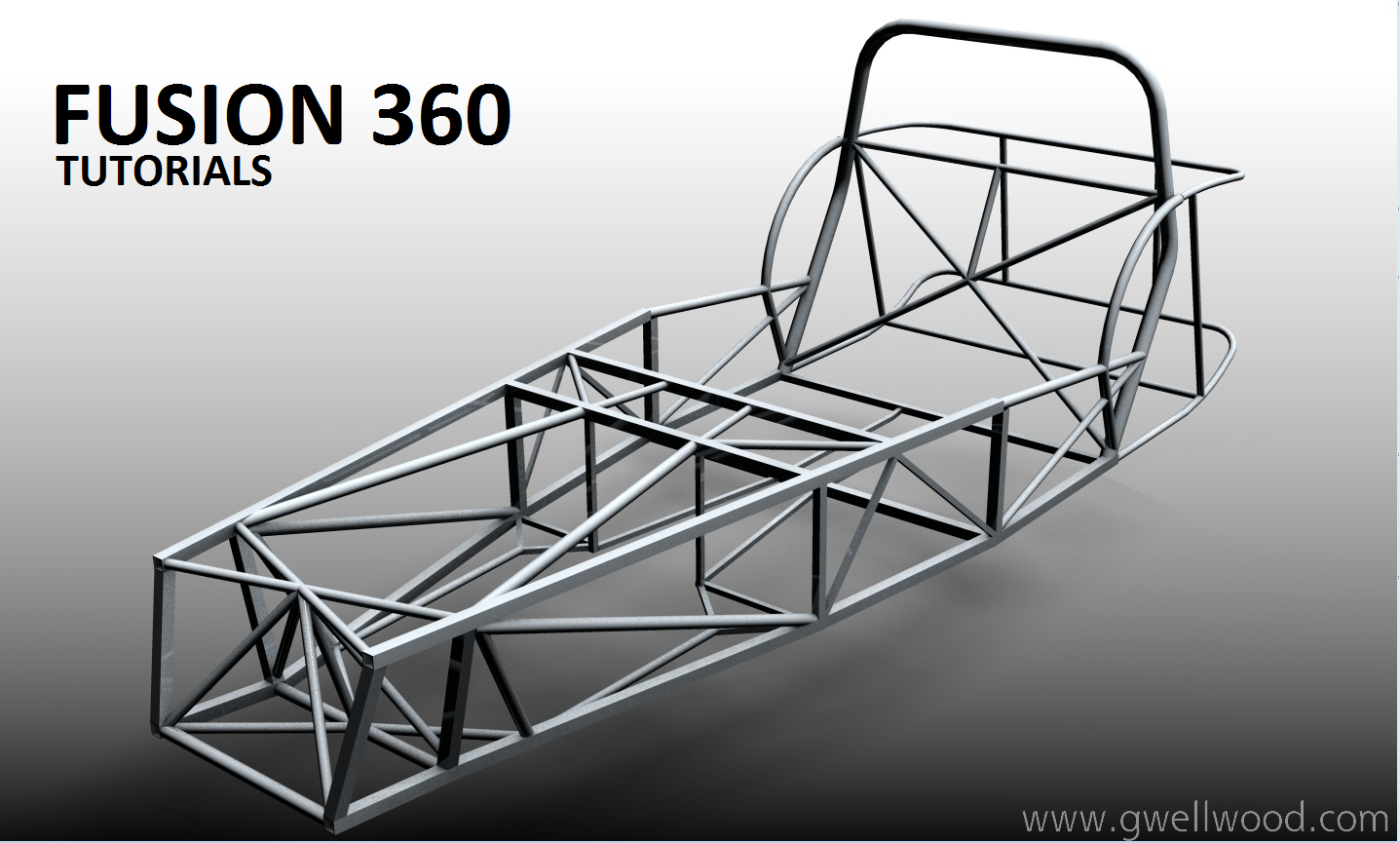

TUTORIALS

Adapted from Carnegie Mellon University Department of Engineering Pro/E Tutorials

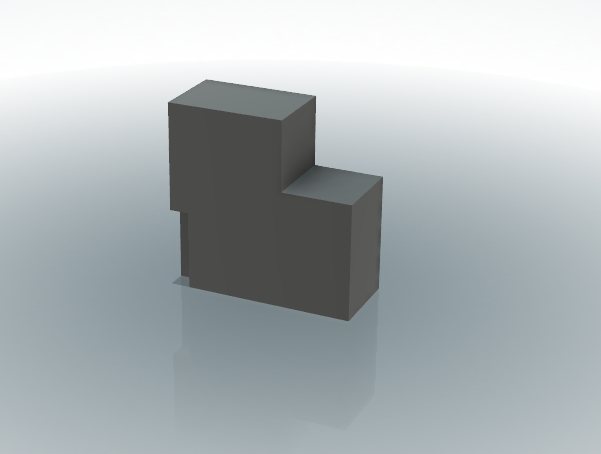

Extrusions, Sketching, & Cuts (TTED Jan 9)

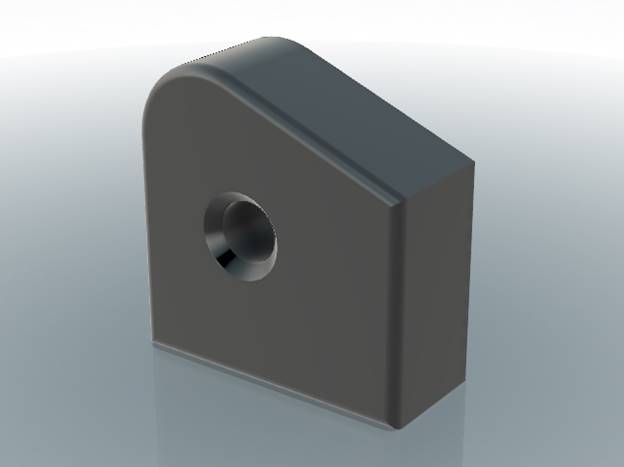

Holes, Rounds & Chamfers (TTED Jan 9)

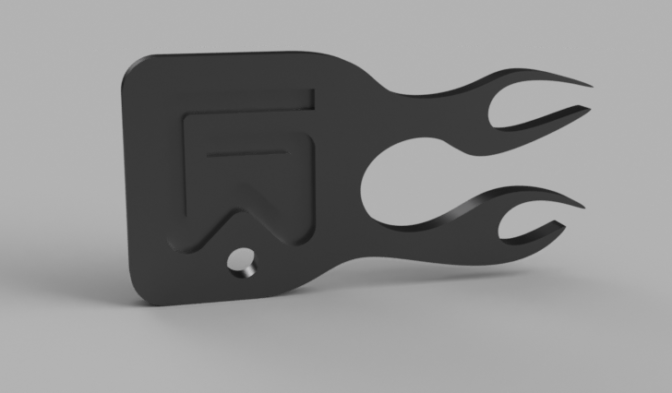

GET CREATIVE! PROJECT: KEYFOB

Shells, Ribs & Work Planes (TTED Jan 11)

Feature Modification & Manipulation (TTED Jan 11)

Revolves, Patterns & Copies (TTED Jan 16)

Sweeps & Lofts (TTED Jan 18)

DIMENSIONING

All Manufacturing and Fabrication industries depend on Drafting. Without Drafting, nothing can be manufactured.

The “drawings” that companies use to “Work” from are called “Working Drawings.” A Working Drawing must have enough information that someone could build the object as specified.

A Working Drawing must include:

-

- All the necessary views to explain the shape

- All the dimensions and specifications needed to build the object to size, using the proper materials

ASK YOURSELF – “Can this object be built without further instructions?”

We need to talk DIMENSIONS

-

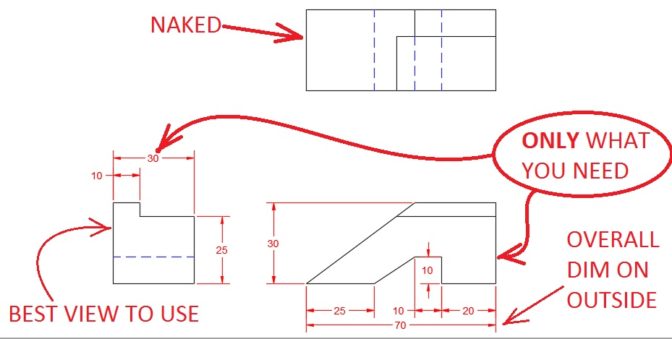

- One view is dimensioned AS MUCH AS YOU CAN

- On one view has WHATEVER ELSE YOU NEED

- THE LAST VIEW IS NAKED

ONLY show the dimensions you NEED to show to BUILD the object – NOTHING MORE.

DO NOT DIMENSION EVERY SINGLE LINE THAT EXISTS! – Be lazy! Only the work you HAVE to.

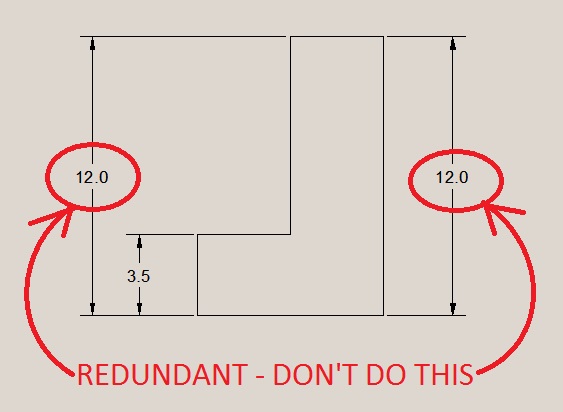

NO REDUNDANT DIMENSIONS (never dimension the same thing twice!).

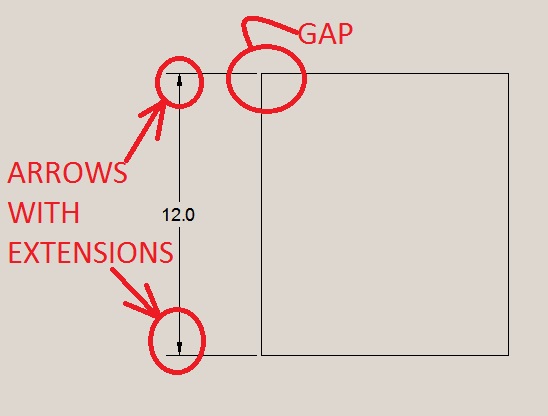

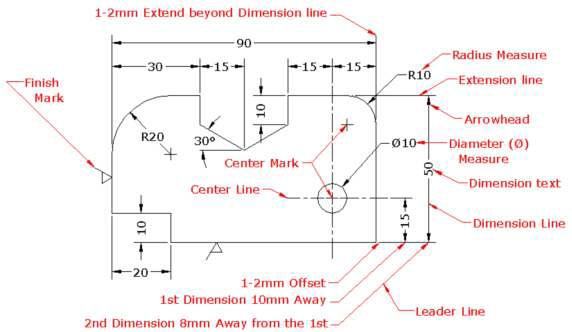

Dimension lines have ARROWS pointing to EXTENSION LINES.

Extension Lines DO NOT touch the object.

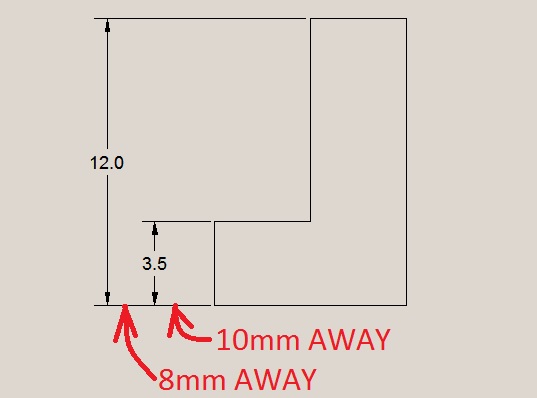

Dimension lines start 10mm from the object and then 8mm apart from each other

Overall dimensions are OUTSIDE smaller dimensions and SHALL NOT CROSS

Do not duplicate dimensions

Do not duplicate dimensions

Do not duplicate dimensions

Do not duplicate dimensions

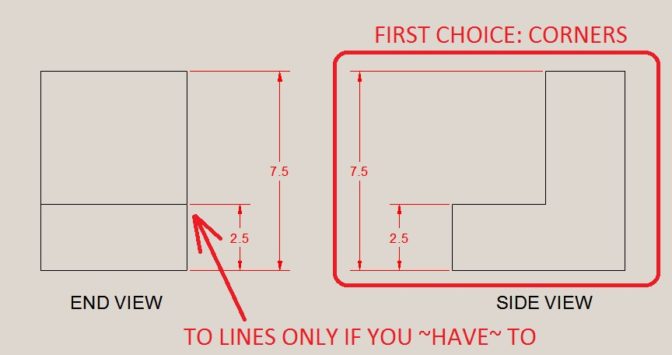

Dimension on the CLEAREST VIEW, usually:

-

- First: on the front view

- Secondly: on the top view (though in this example, the end view is more clear)

- Lastly: only if needed, on the side view

Dimensions go BETWEEN THE VIEWS

Dimensioning to CORNERS is better than LINES

DO NOT Dimension to hidden lines

(if you dimension to hidden lines, I’m going to punch you in the hidden line)

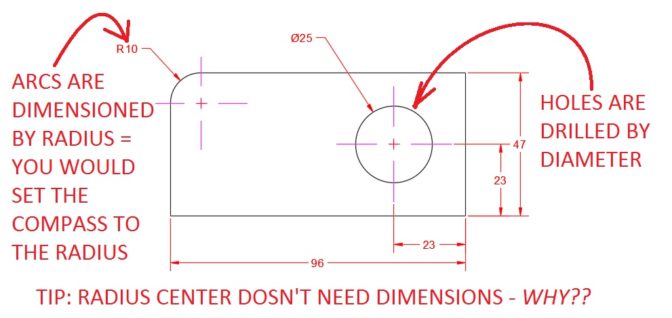

ARCS are dimensioned by RADIUS (you use a compass to draw them)

HOLES are dimensioned by DIAMETER (you use a drill to cut them)

YOU MUST DIMENSION HOLE CENTERS!!! (Where is the hole located??)

All-in-one Example

ENGINEERING DRAWINGS (Working Drawings) (TTED Jan 18)

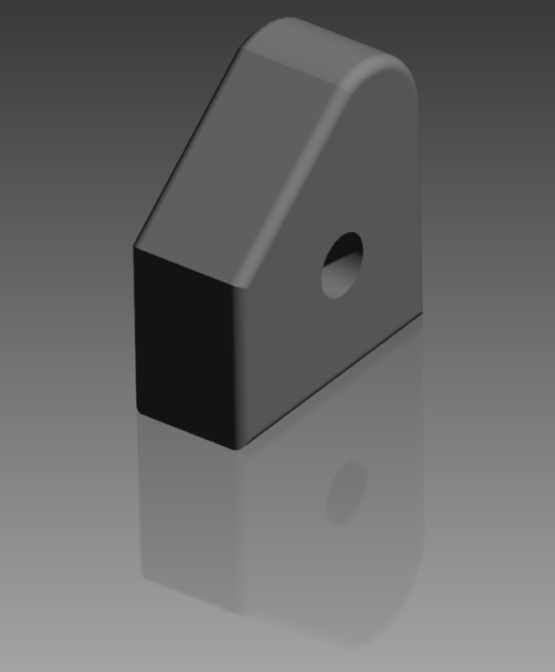

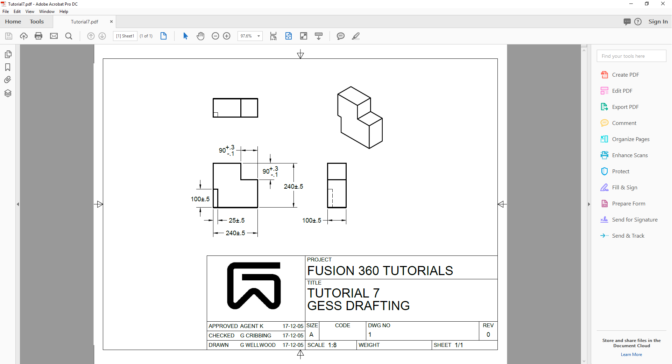

Problem 7a – Create Engineering Drawings for Problem 1

Problem 7b – Create Engineering Drawings for Tutorial 4

-

-

-

- Dimension the location of the hole?

- Dimension the size of the hole?

- Dimension the center of the Radius?

- Dimension the size of the radius?

- Dimension the radius on the edges?

- Dimension the overall height?

- Dimension the overall width?

- Go back and read the rules of dimensioning

-

-

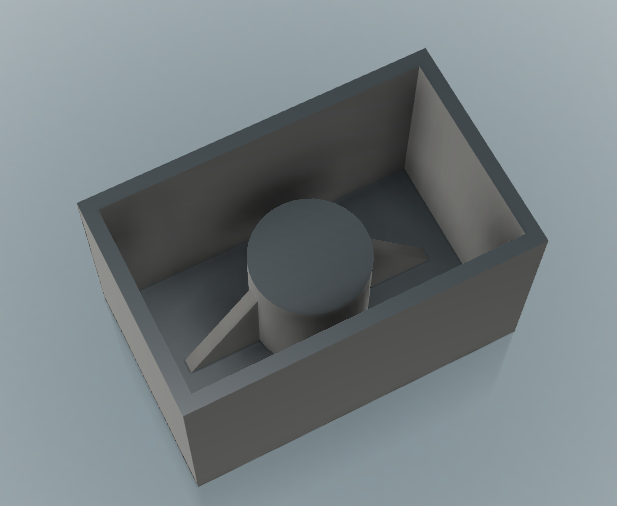

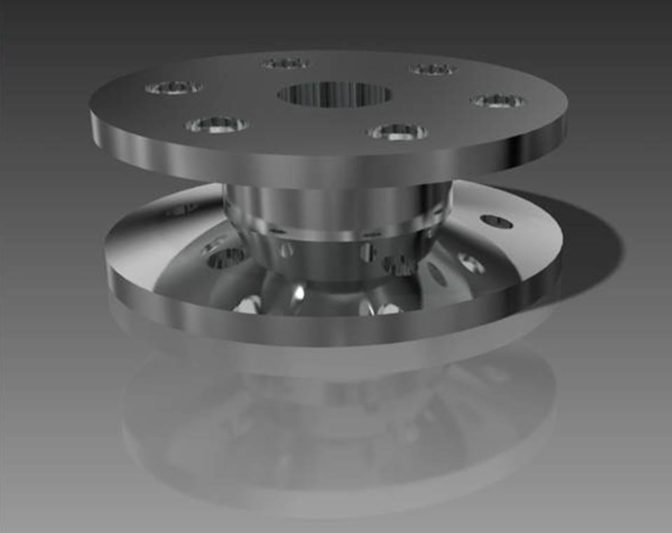

Problem 7c – Create Engineering Drawings for Tutorial 5

-

-

-

- Dimension the shape of the revolve?

- Dimension the sizes of the holes?

- Dimension the distance of holes from center?

- “Leader” to say “C-BORE” and counterbore size?

- Go back and read the rules of dimensioning

-

-

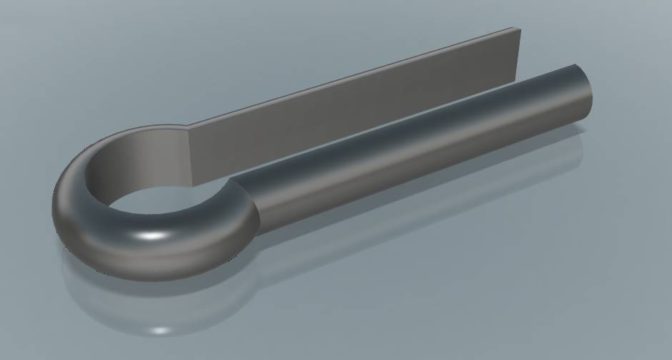

Problem 7d – Create Engineering Drawings for Tutorial 6A (Hair pin)

-

-

-

- Dimension the path?

- Dimension the profile?

- Convince me that you’ve learned this

-

-

SHOW your instructor the Problems on screen (I want to KNOW that you got this), then send the PDFs to the handin folder.

DO NOT CONTINUE WITHOUT BEING CHECKED!

Assembly Modeling (TTED Jan 23)

Sheet Metal Design (TTED Jan 23)

GET CREATIVE!

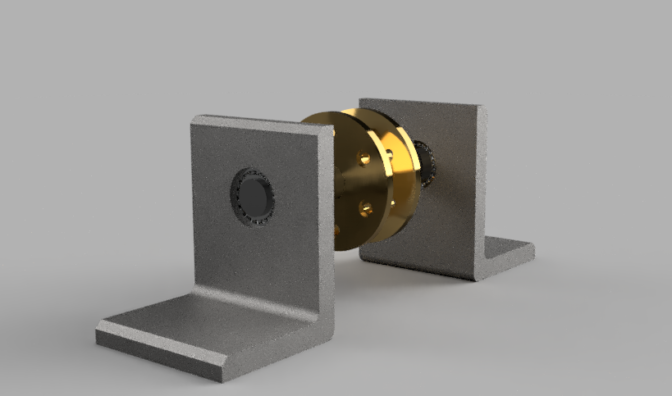

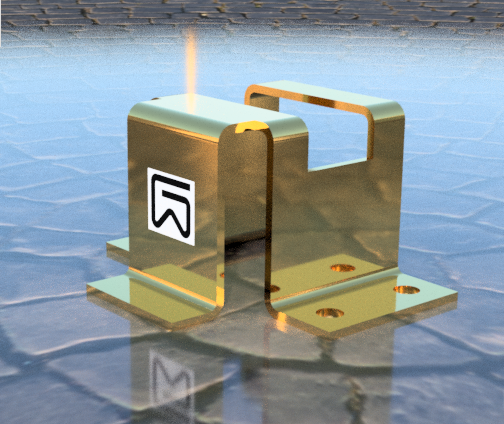

FUSION 3-PART CHALLENGE!

(TTED FEB 8)

This Project must be completed THIS TERM;

Don’t waste your time

Don’t waste OTHER PEOPLE’S time;

THEY NEED TO COMPLETE THEIR PROJECT TOO

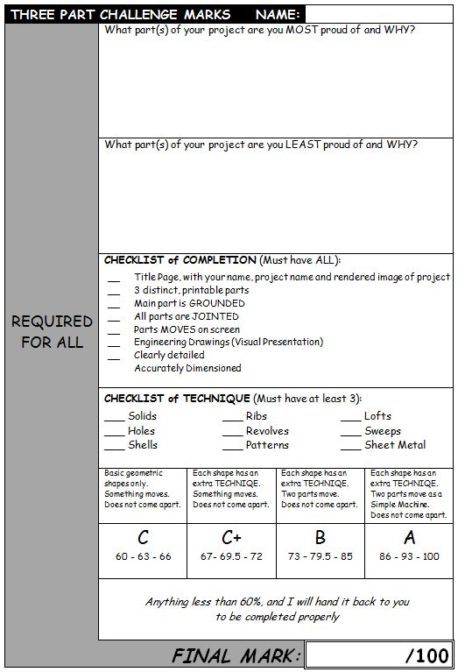

CLICK HERE TO PRINT MARKS SHEET

THE PROJECT MUST:

-

- Be a GADGET, TOOL, or CONTAINER

- (check out the MARKS SHEET – the HOOP you must jump)

- A: Each shape has extra techniques, TWO parts move as a SIMPLE MACHINE, and, when 3D Printed and assembled, does not come apart.

- B: Each shape as extra techniques, TWO parts move, when 3D Printed and assembled does not come apart

- C+: Each shape has extra technique, something moves, when 3D Printed and assembled does not come apart

- C: Basic geomteric shapes, something moves, when 3D Printed and assembled does not come apart

- !!MOVING PARTS MUST HAVE ABOUT 1.5mm CLEARANCE!!

- (check out the MARKS SHEET – the HOOP you must jump)

- Be ASSEMBLED from ONLY THREE DISTINCT PRINTABLE ASSEMBLEABLE parts

- A Single Part can have more than one technique applied

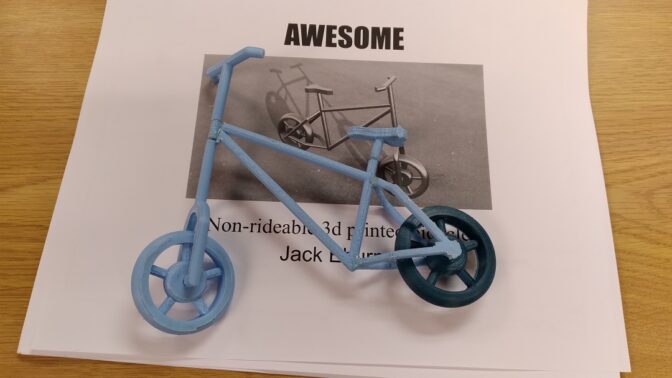

- “Single Part” example: A bicycle wheel (though it is made of many pieces, it is considered ONE part):

- Rim (revolve)

- Hub (revolve, hole, pattern)

- Spokes (sweep, thread, solid)

- Tire (revolve, solid, pattern)

- Valve stem (revolve, thread)

- You have permission to use “real” screws, springs, metal pins, and the like, as fasteners if need be

- Something MUST MOVE yet remain ATTACHED When 3D printed and assembled

- Use at least THREE DIFFERENT TECHNIQUES:

- Solid modeled parts

- Holes

- Shells

- Ribs

- Revolved parts

- Patterns

- Lofted parts

- Swept parts

- Sheet Metal

- Be a GADGET, TOOL, or CONTAINER

HAND IN THE FOLLOWING:

-

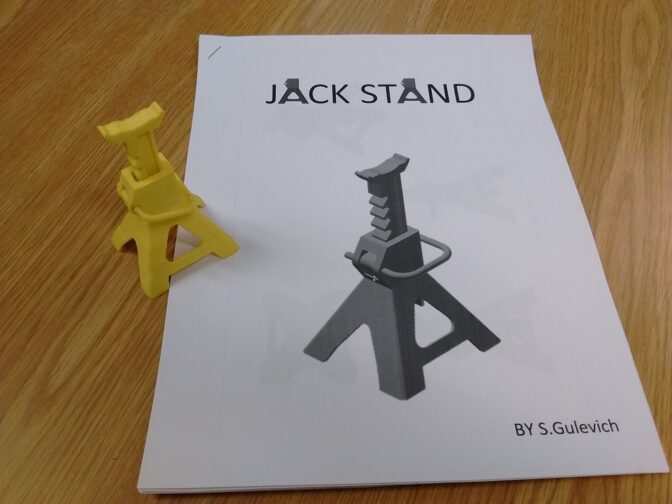

- PRINTED 3D – Project (Click HOW TO 3D PRINT)

- PRINTED Engineering Drawings Booklet (PDF) (IE: Tutorial 7?)

- Page 1: TITLE PAGE with RENDERED VIEW (RENDERED!!!)

- Page 2: ASSEMBLY (no dimensions) (Use the “+” to add pages)

- Pages 3, 4, 5, etc…: PARTS – one page for EACH individual part (with dimensions)

- PRINT for marking

- Click for AWESOME Example

- EXPLODED ANIMATION (IE: Tutorial 8?)

- EXPORT All *.avi files

- DIGITAL – ALL Project Files

- EXPORT All *.f3d *.jpg *.doc & etc. files

- CREATE A FOLDER labelled lastname_projectname, and COPY ALL your files into it.

- example: wellwood_sheet-metal-brake

- DRAG AND DROP the folder to “i:\1. Handin\!Wellwood”

- PRINTED MARK SHEET (below)

- PRINT for marking

- YOU mark yourself FIRST

- Click for Mark Sheet

- GO BACK AND FOLLOW THE PREVIOUS 5 THINGS (above)

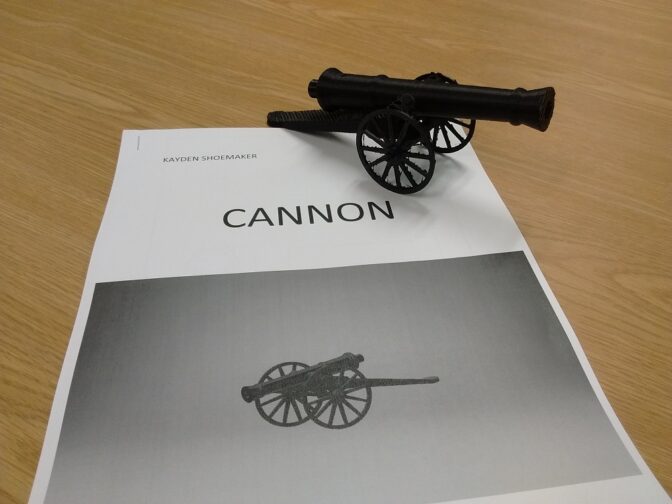

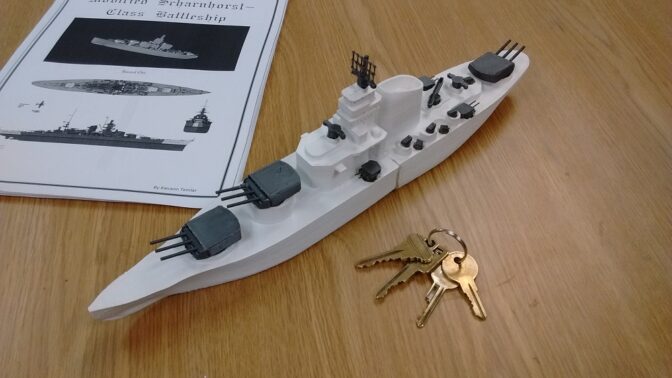

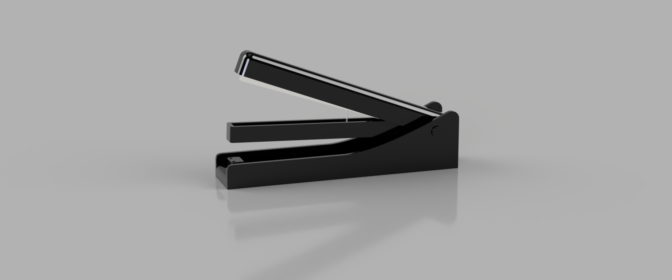

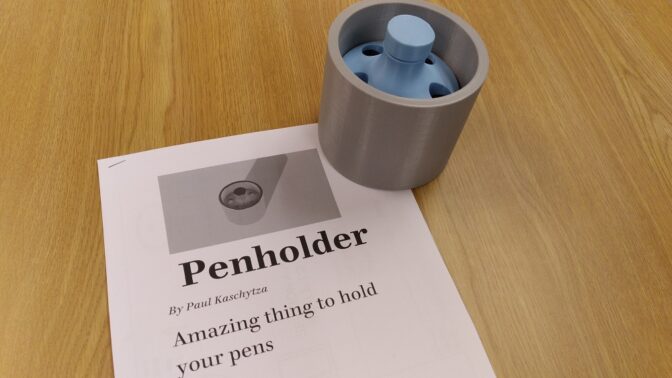

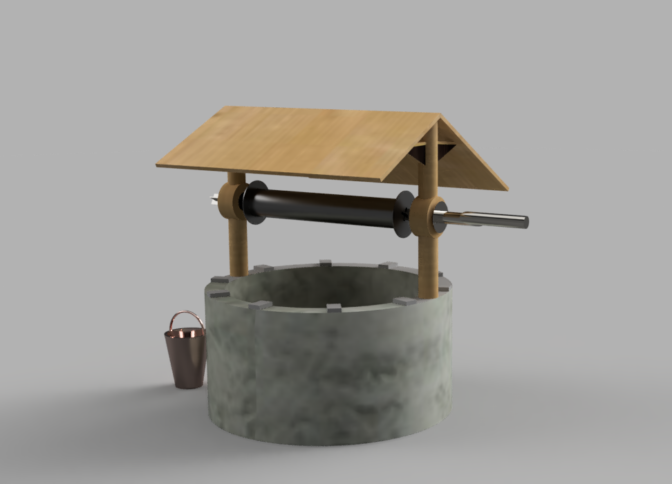

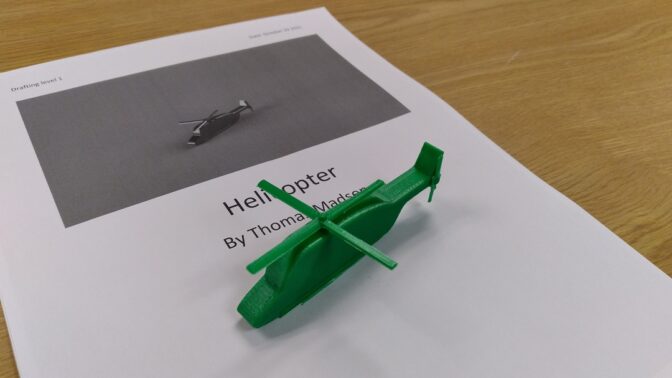

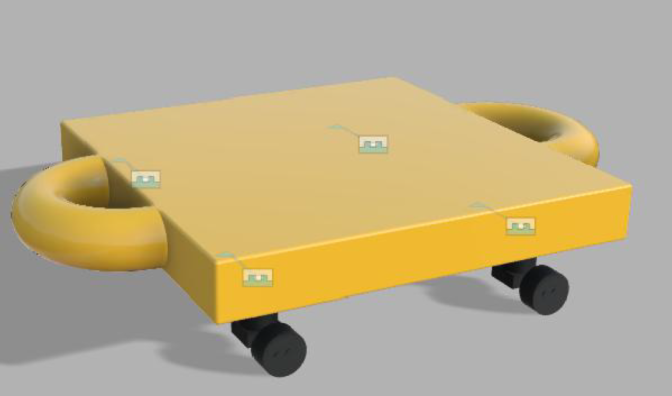

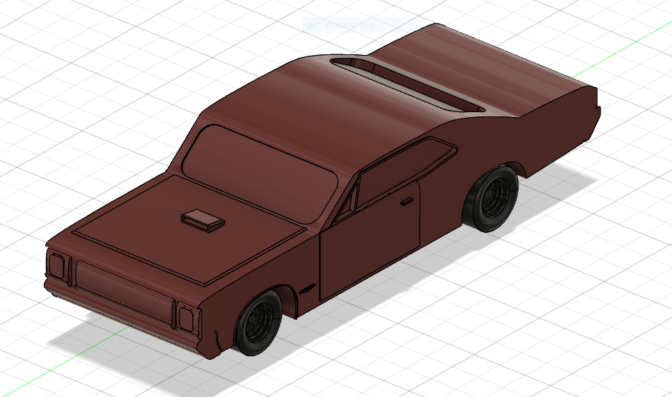

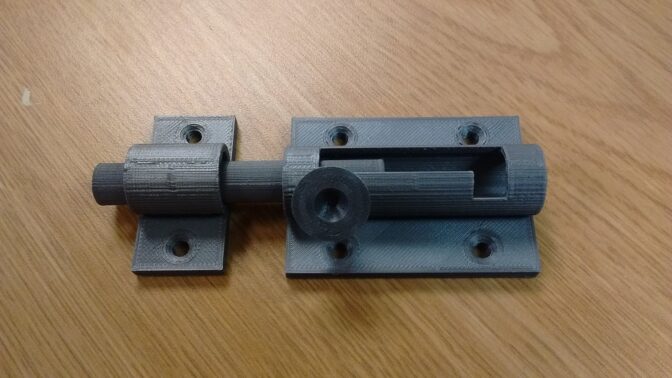

PAST EXAMPLES

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FINISHED?

Carry on into Architecture! That’s is a big unit too

Try to get ahead in case things slow you down!!

Three Part Challenge Top Ten

This assignment is new this year – no examples yet.