[Engine Performance] [Balancing & Blueprinting] [Boost & Nitrous] [Automatics] [Differentials] [Lifting & Lowering]

QUESTIONS – Differentials(Updated Nov 2022) |

PURPOSE |

|

“Differential” (our main topic at hand) usually carries the Final Drive Gears. The Final Drive gears ultimately set the vehicle’s balance between acceleration (power) and speed (fuel economy). Kind of like riding a one-speed bicycle, you can’t really have both. The lower the gear ratio (like 3.08:1 vs. 4.56:1) the better the fuel economy, but the slower the acceleration or pulling power. In a typical Rear Wheel Drive (RWD) setup with an inline drivetrain, the power has to split 90° to drive the wheels, and these use a “Ring & Pinion” gear set. In a typical Front Wheel Drive (FWD) setup with a Transverse drivetrain, the Final Drive is typically meshed together a lot like the gears inside a manual transmission, and are often a Helical Gear Set. In this unit you are going to learn how to set up a Ring & Pinion gearset. The Differential also needs to drive the wheels at different speeds to negotiate a corner. Without a differential, you vehicle will want to only go straight, because the drive wheels will determine the direction the vehicle travels, not you. The purpose of the Differential itself is to allow both drive wheels to still be driven by the motor but also be able to turn at different speeds so you can go around corner. To make it awesome, you’re going to need a Limited Slip Differential (LSD). We’ll focus on those in a bit In this unit you are going to learn the different types of LSDs, their advantages, and disadvantages.

|

COMPONENTS |

|

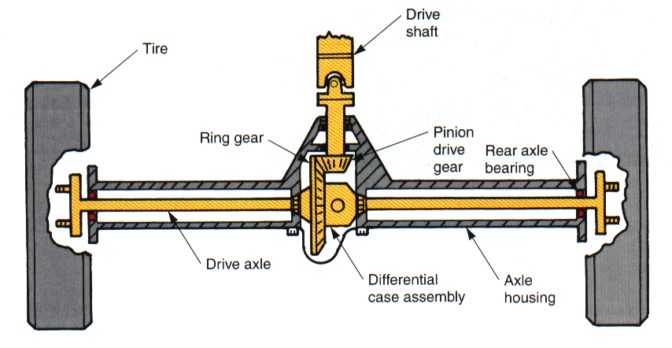

In a conventional rear wheel drive, a beam axle assembly encloses the final drive gears, differential and axle shafts in one housing. A ring gear (also called crown wheel) and a pinion gear transfers the drive through ninety degrees, and provides a final gear reduction to the driving road wheels. In order for the gears to operate durable and quietly, the gears must mesh exactly. Taper roller bearings support the pinion in the carrier. The companion flange splines engage with the pinion splines, to transfer the drive from the drive shaft. A collapsible spacer, between the bearings, allows the pinion depth to be adjusted in relation to the crown wheel. The ring gear is bolted to the differential case, which is supported in the carrier by taper roller bearings, retained by bearing caps and bolts. Threaded adjusting rings engage with threads in the carrier, and are used to set the back-lash clearance between the ring and pinion. In some differentials (such as GM), shims of specific thicknesses are used instead of a threaded adjuster. Some manufacturers (older Hyundai) allow no method of adjustment, apparently leaving it all up to fate. With the carrier bolted to the axle housing, the splines on the axle shafts can engage with the splines of the differential side gears, and drive is transferred through the differential case and gears, to the road wheels. DifferentialIf the vehicle had both rear wheels solidly connected together, much like a go-kart, the vehicle would be a nightmare to steer. When a car turns, the inside wheels must turn a smaller circle than the outside wheels. Because the vehicle has a constant speed through the turn, the outside wheel must turn at a faster speed than the inside wheel. A differential allows there to be a difference in speed between the wheels, yet still apply power to the drive wheels.

|

WHERE IT FALLS APART |

|

In a performance or off-road application, the regular “open” differential will show its weakness – when traction is lost on one wheel, that wheel will begin to slip, and then ALL the power is applied to that slipping wheel, and zero is applied to the wheel with traction. It sucks, but it’s true. The solution is to LIMIT the SLIP with a special differential called a Limited Slip Differential (LSD). By now you have probably noticed that we’re not very creative with names. Manufacturers have used a variety of methods to to create some LSD action:

|

CLUTCH PACK |

|

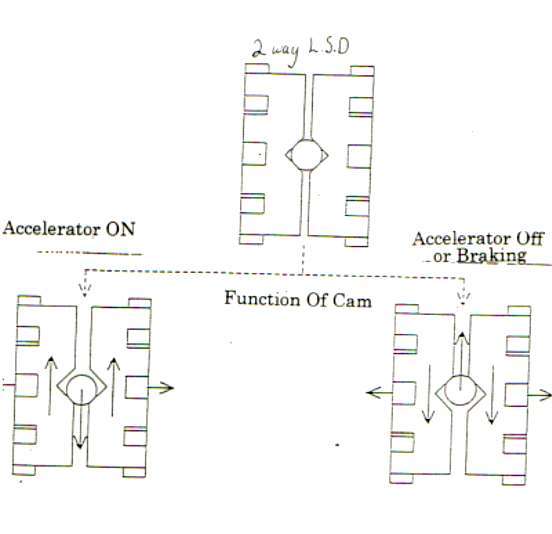

(Most Common) Spring-loaded clutch discs and plates added between each axle gear and the differential case. Sometimes “chatters” on turns. This differential is Power Sensitive, meaning that it “locks” when power is applied, and “unlocks” when power is not applied. A “1-way” LSD will lock under power only. A “2-way” LSD will lock on both power and deceleration, but will “unlock” when you coast. A “1.5-way” LSD locks under acceleration, and locks less aggressively under deceleration.

|

CONE CLUTCH (Auburn) |

|

Spring-loaded cone-shaped axle gears applying friction against the differential case at all times. Non-rebuildable

|

RATCHET |

|

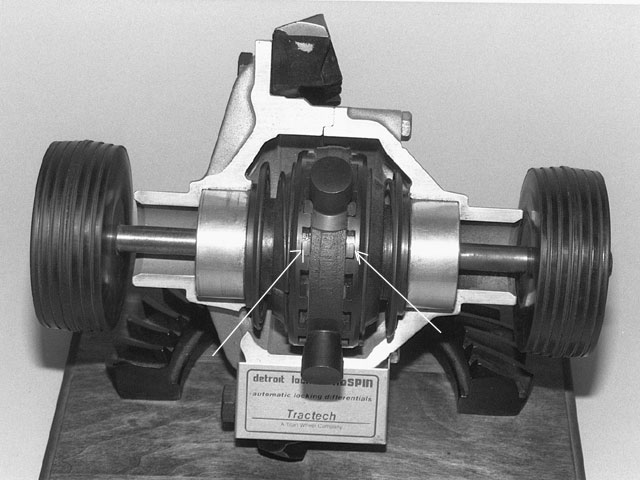

Also known as The “Detroit Locker” (this information taken from www.fourwheeler.com) Also called the NoSpin, the Detroit Locker is generally regarded as the granddaddy of all lockers currently available. The Detroit Locker was originally made by Tractech (now Eaton) and is a positive-locking traction device that locks the two axle shafts together when engine power is applied. This unit is completely mechanical and requires no wires, plumbing, or other pieces. It has been on the market for many years, and its design borders on ingenious because of its simplicity. Time has proven this locker to be the strongest, most bulletproof mechanical locker on the market.

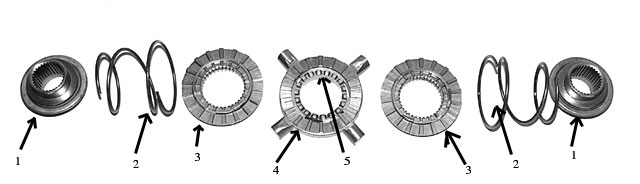

Components:1. Side gears 2. Exterior springs 3. Driven-clutch assemblies 4. Spider assembly 5. Center cam

Locking on Power:

When the vehicle is under power and moving forward, both axle shafts are locked in position and turn at the same speed. The key to the whole operation are the teeth (arrows) on the spider assembly and the driven clutches on either side of the spider assembly. The driven clutches ride between the side gears, which are splined onto the axle shafts and turn at the same speed as the axles.

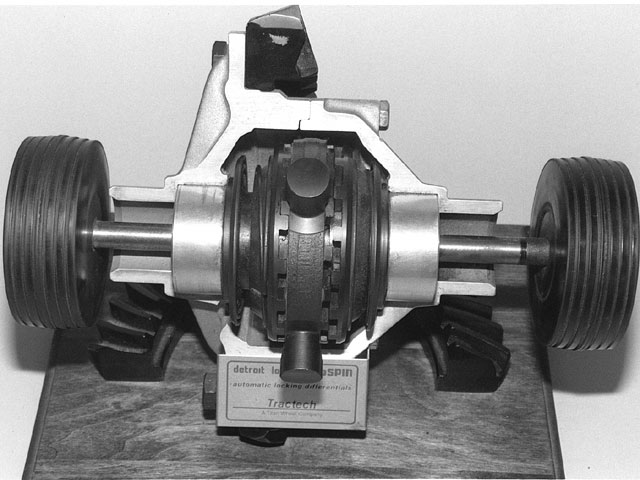

Unlocking for Turns:

This photo indicates what happens coasting around a left-hand turn. During a turn, the outside wheel must travel a greater distance than the inside wheel, so the outside wheel must travel faster. The teeth on the spider and driven-clutch assemblies are cut at a 5-degree negative angle. When you are coasting around a corner, the outside wheel is forced to turn faster by the surface of the road. The center cam (inside the spider gear) acts as a ramp to disengage the right driven-clutch teeth from the spider gear. This allows the right axle shaft to rotate faster around the corner. Once the driven-clutch rotation equalizes and both wheels are traveling at the same speed, the exterior springs force the teeth to mesh again

Just so you understand: If you are in a corner and coasting, you will be fine – the outer wheel will free wheel. If you apply power, the diff will lock and your vehicle will immediately point towards the ditch. If you freak out and immediately lift, the vehicle will now immediately head for the centerline. You won’t want this on a short wheel base vehicle, or with low profile tires that do not flex to absorb some of this action.

|

TORSEN |

|

A locking differential that uses a complex series of worm gearsets. Very smooth application of power, but becomes “open” if one wheel has zero traction. This differential is Torque Sensitive. Probably the best for FWD. They tend to feel “invisible,” and upset the car’s balance and handling the least in operation. Here is an article about the operation of the Torsen Differential, published by the Institute of Mechanical Engineers (IMechE):

This is probably my all-time favourite differential for a street vehicle. It is the LSD that is least likely to send you into the ditch in winter, yet still propel your forward.

|

VISCOUS |

|

Uses a sealed cavity between the axle gears with a special fluid and vanes that resists a difference in speed. Much like a torque converter as a fluid coupling, this is a speed sensitive differential.

|

EATON LOCKING DIFFERENTIAL |

|

A Speed Sensing differential Acts as an open differential, until the difference in speed between the two wheels is great enough, then it engages. This is a factory GM locking differential, used for many years under the SPID (Service Parts IDentification) code “G80” (look for the sticker in the glove box or under the hood), often called the “Gov-Lock”

Also called the “Gov-Bomb,” because sometimes when it locks, it explodes.

|

FLUIDS |

|

Most differentials use 80W90 gear oil. When running a clutch-type limited slip, either limited slip gear oil or a special friction additive must be used so the clutches will last. GM has a a good additive that is compatible with most limited slips. There is zero harm in running a LSD oil in an open diff. Giv’er.

|

SETUP |

|

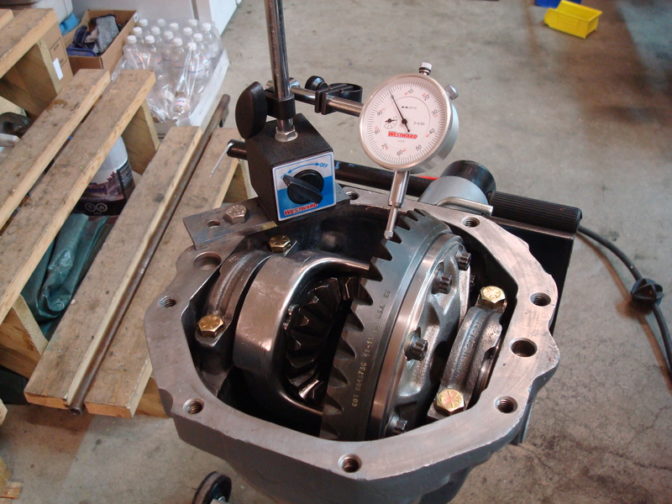

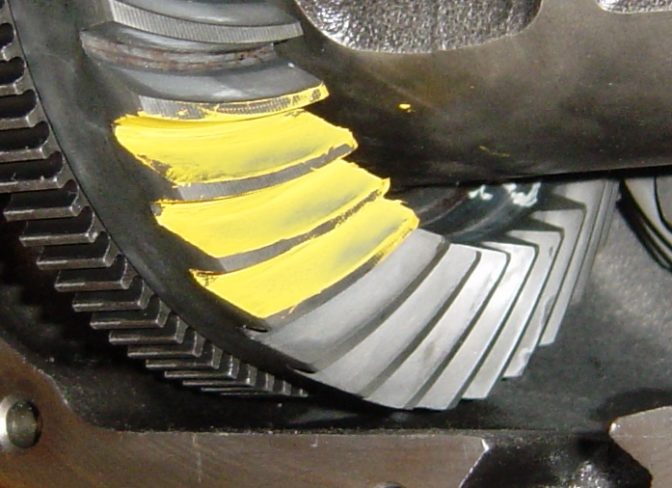

Setting up a differential can be time-consuming. However, if it is not done correctly, a noisy differential can be the result at best, and at worst the ring and pinion can be completely wiped out. It is important to always follow the factory manual in setting up the differential. In addition to basic sockets and wrenches, you will need a dial indicator and a magnetic base. The wear pattern is normally checked with a gear-marking paint. You must know the following parts of the gear teeth Here is the basic setup procedure for a common differential

INSPECTIONInspect all bearings and gear surfaces for any wear, defects or discolourations You don’t want to do all this work only to have to do it again due to a failed part

PINION DEPTHPinion depth is normally set by shims Start with the shims the differential came with You can change later once you’ve installed the carrier and set the back lash

PINION PRE-LOADThe pinon gear bearings require a certain amount of “pre-load” as measured for resistance on a beam-type torque wrench This is accomplished by tightening the pinion nut further, which also changes pinion depth This is a time-consuming delicate balance

BACK LASHInstall the carrier and bearings Tighten both the left and right adjusters evenly by hand until they are fairly tight Check backlash with a dial indicator pointing at a ring gear tooth. Hold the pinion gear, and rotate the ring gear, measuring the amount of play between the ring and pinion gear teeth. If the backlash is too wide, tighten the left adjuster until the backlash is correct If the backlash is too tight, tighten the right adjuster until the backlash is correct If necessary, open one adjuster and tighten the other Both adjusters must be fully hand tightened when acceptable backlash is obtained The final adjustment should tighten the left adjuster since the ring gear is forced away from the pinion gear while under load

PATTERN CHECKWipe some gear-marking paint on three or four teeth Load the ring gear with one hand, while turning the pinion with your other hand back and forth Observe the pattern, and adjust pinion depth (and backlash, since it will change) accordingly

|

SPOOLS |

|

Not a “Differential” at all, but I think it’s worth mentioning. A Spool physically locks both left and right axles together permanently and for always. The outside wheel will ALWAYS turn at the same speed as the inside wheel. A Spool should NEVER be used on pavement.

This places very high loads on the axle shafts themselves when you try and turn. You should expect to be shearing axle shafts frequently. In GM vehicles (and others), if you break an axle, you will lose the wheel, the brakes, and the axle shaft from the vehicle since the axle is held in place by a wee “C” clip inside the differential. A Spool belongs in a drag car – something that goes straight and does not have to turn, a dirt car – something that can always be skidding the tires without stress, or a drift car – something that is always sliding sideways. Cheap people sometimes weld their differentials solid – called a “Lincoln Locker” after the Lincoln brand of welders. Not only do you risk shearing axle shafts, but the welding ruins the spider gears and the carrier and the bearings, parts of which often explode and take out everything.

|