REVIEW?

Do you remember how to creating mechanized components Within an Assembly? (Review)

POTENTIAL REVIEW ASSIGNMENT:

Until I get everything uploaded and accessible…. Go to the school server DATA drive, I:\Wellwood\Don’t Click Me\Metal\Plans and pick something that amuses you, has no more than 5 parts, and something that moves.

MODEL it in Fusion360

FEA-TEST the most major component of the project, and determine how much force the item can take.

CREATE DRAWINGS of each part, fully, accurately, and clearly dimensioned. Include one page for the assembled project.

RENDER a sweet view of the finished product. Pick a sweet background.

REALITY: I MAY JUST HAVE YOU SKIP THIS, DO SCULPTING, AND THEN JUMP STRAIGHT INTO SOMETHING AWESOME AS THE CHALLENGE RIGHT FROM THE START

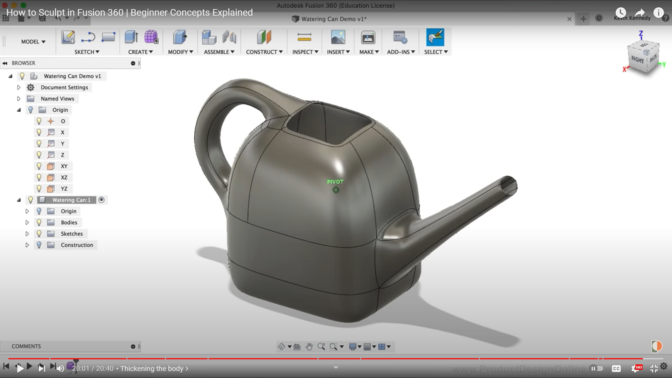

TUTORIAL: SCULPTING

Follow THIS VIDEO and sculpt a Watering Can:

SHOW your instructor on the screen FOR MARKS!

FUSION CHALLENGE: GET CREATIVE!

If you are not here by October 1st/March 1st, you’re going to run out of time

This Project must be completed THIS TERM;

Don’t waste your time

Don’t waste OTHER PEOPLE’S time;

THEY NEED TO COMPLETE THEIR PROJECT TOO

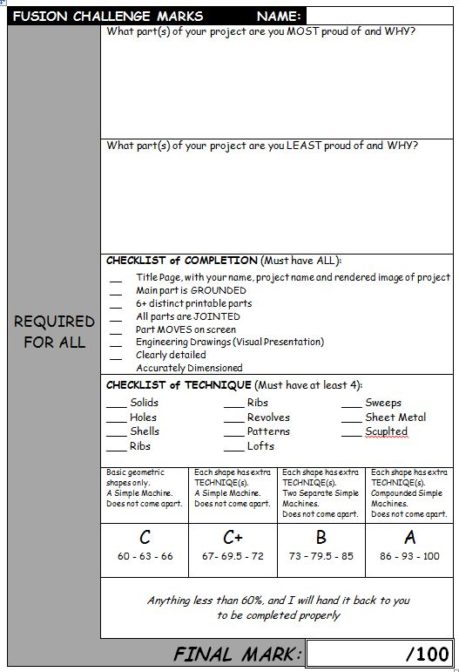

READ THROUGH THE MARKS SHEET

THE PROJECT MUST:

-

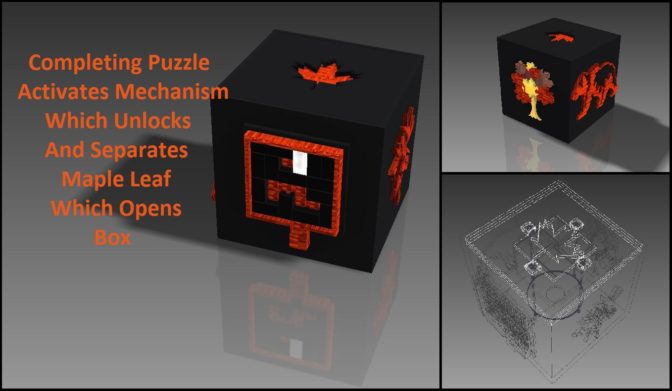

- Be contained in a SCULPTED enclosure/body/container/package/component

- Can be a part of it, or removable from it

- Be a MECHANISM (a system of parts working together as a Simple Machine)

- A: Each shape has extra techniques, COMPOUND SIMPLE MACHINE (machine moves another machine), does not come apart.

- B: Each shape as extra techniques, TWO simple machines, does not come apart

- C+: Each shape has extra techniques, A simple machine, does not come apart

- C: Basic geometeric shapes, simple machine, does not come apart

- !!MOVING PARTS MUST HAVE ABOUT 1.5mm CLEARANCE!!

- Be a MECHANISM that IS a SIMPLE MACHINE << click to know what a Simple Machine is

- Be a Simple Machine

- Be no larger than the size of your hand

- Still be a Simple Machine

- Be ASSEMBLED from 6 or more distinct, assemblable parts

- “Single Part” example: A bicycle wheel:

- Rim (revolve)

- Hub (revolve, hole, pattern)

- Spokes (sweep, thread, solid)

- Tire (revolve, solid, pattern)

- Valve stem (revolve, thread)

- “Single Part” example: A bicycle wheel:

- Use at least SIX of these (Sculpting is REQUIRED):

- Solid modeled parts

- Holes

- Shells

- Ribs

- Revolved parts

- Patterns

- Lofted parts

- Swept parts

- Sheet Metal

- Be contained in a SCULPTED enclosure/body/container/package/component

10% BONUS: do FEA on TWO components of your project

CLICK HERE TO PRINT MARKS SHEET

Complete model and show to instructor ON SCREEN, and then….

HAND IN THE FOLLOWING:

-

- PRINTED 3D – Project (HOW TO 3D PRINT)

- PRINTED – Engineering Drawings Booklet

- #1: TITLE PAGE with RENDERED view

- #2: DRAWING of Assembly (no dimensions)

- #3… DRAWING for each individual part (with dimensions)

- Click for AWESOME Example

- EXPLODED ANIMATION

- Export all *.avi files

- DIGITAL – Entire Project

- Export All *.f3d *.jpg *.doc & etc. files

- MARK SHEET (below)

- You mark yourself first

- Click for Mark Sheet

DIGITAL FILES:

-

-

- CREATE a folder labelled lastname_project-name (Example: wellwood_sheet-metal-brake)

- SAVE everything into this folder

- DRAG AND DROP the folder to “i:\1. Handin\!Wellwood”

-

CLICK HERE TO PRINT MARKS SHEET

FINISHED?

Carry on to Architecture! That’s is a big unit too

Try to get ahead in case things slow you down!!

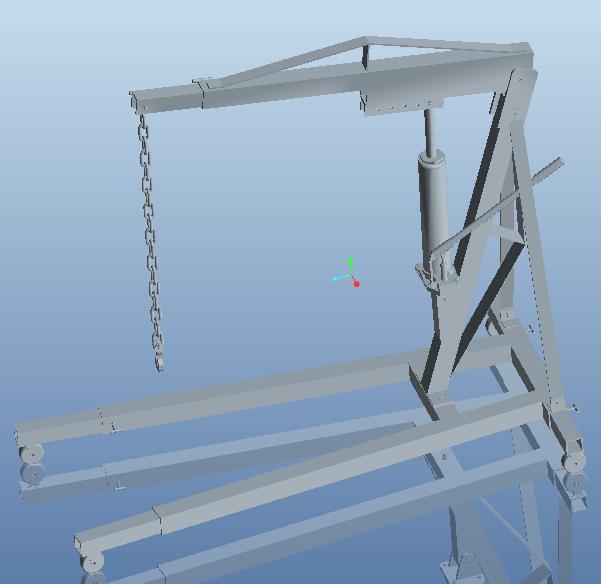

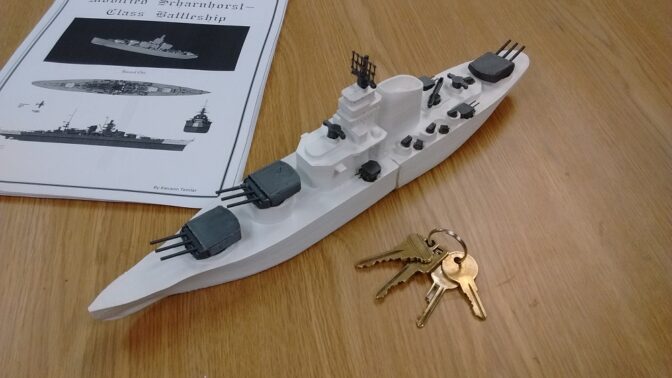

PAST EXAMPLES

|

|

|

|

|

|

||