This goes through the “Intro” page, as a sequence of events.

How I teach the course:

The course begins with a run-down of the Course Outline, expectations, how I mark, and what needs to be completed.

Then I begin working through the Intro section, starting with Sketching, Isometric and Orthographic. I tend to teach to the fastest kids, who don’t really need my help. That frees me up to help the stragglers, or the ones who DO need my help. Kids need to be able to read a drawing.

Then I teach Dimensioning. I have the worksheet as a CAD drawing, which I dimension on the screen and the kids follow along. Then they work through the Dimensioning Assignment. Kids need to be able to read dimensions.

This all will have taken about 5 or 6 hours.

Then I cover safety. Eyeball video for sure, with a warning – “if this grosses you out, just close your eyes, don’t look. If this fascinates you, consider a career in Medicine – we need people who are fascinated by this.” PowerPoint with lots of stories, but mostly how to avoid being hurt. Then demonstrate all the machines, and safety quiz.

Safety Booklet and Tool Box assignments are good for substitute days – you’re not likely going to get a “shop sub,” so have something educationally relevant that anyone can do.

I spend a bit of time talking about Time Management, and how best to maximize the time I spend helping kids.

Teach Fractional Measurement, because they’re going to need it next.

Then we start the first project: Soft Jaws (Level 1), Drill Point Gauge (Level 2), and Lathe Bit Gauge (level 3). With Soft Jaws, I mark the best of the two. I teach the Level 2’s how to sharpen a twist drill, and when it is acceptable I mark their drill gauge. Level 3’s sharpen a Lathe Bit and I mark it when the sharpening is acceptable. I tell the kids that “This project shows me which ones of you can’t follow instruction.”

The first kid done the Soft Jaws begins the Machinist’s Hammer. I will ask them a wack of questions (“how far from the end is the drilled hole? What size are you going to drill that hole? How far from the other end does the taper begin? What size if the curve on the end of the taper? What size are the chamfers on the beating end of the hammer? What do you need to know about cutting threads so you don’t break the tap off in your project?). Once the kid successfully answers the questions, they get the hammer head material. Grilling them with questions before they get material has increased quality substantially! It FORCES them to actually read the plans in advance. You will be surprised how many kids will put the plans away and never reference them again. I have no idea what they are hoping for….

When the first kid is at the point of cutting threads, I give the Taps & Dies assignment and teach reading a Tap Drill Chart, and tapping the hole. I usually do the demo on the kids project for extra attentiveness, being fairly expressive that “I hope I don’t break the tap off in here, because they are a bugger to remove…”. Play that up.

Once the first kid is done the Hammer Head, I go through the Basic Lathe Procedures booklet, and talk Lathe.

Then questions on the Machinist’s Hammer Handle.

Sometimes I spend time teaching Micrometers, but usually I just teach Dial Calipers one-on-one with each kid at the lathe, so they can use the dials on the Lathe to cut down to D3/8″ with just a bit of Grade 3 Math.

I pretty much cater to the Level 1’s, as I likely have more of them in the class than the 2’s, 3’s, and 4’s.

At some point, the Lathes will be full of students, and the next kids can’t move on. At this point I introduce the Welded Log project, and teach Stick Welding. PowerPoint, worksheet, “go-through-the-motions” demo, Safety Quiz. I usually give a one-on-one demo with each kid when they are about to weld. I don’t really grill questions on the Log, but I give tips based on what kids forget to do (largely, the kids who don’t read the plans).

First kid to be ready to blacksmith the Axe head, and I talk about using the forge and anvil. I do NOT demo ANY blacksmithing, only because I have ruined my arms with hammer work, and even one demo undoes a month of physio for me. I talk about taking care of your arms “guide the hammer, don’t muscle it – use gravity to your advantage!”

First kid ready to Braze the Axe head to the handle, and I teach Oxy-Acetylene Welding. Video and question sheet. Safety Quiz. I usually one-on-one demo Brazing with each kid directly.

At this point things really start to spread out. I try to impress upon the kids the importance of getting onto the Lake Country Chopper project, since I only have two torches. Those torches should NOT be empty. Many kids are afraid of the torch and tend to put that project off. ALL usually find it very enjoyable and therapeutic once they’ve gotten some experience with it.

Whether the kids take on the Collapsible Shovel, or the Lake Country Chopper, or the Twisted Double Hook next, I don’t really care. They all need to be done, and I work with each kid individually depending on what project they take on and in what order.

You will notice I didn’t talk much about the Level 2’s or 3’s (or 4’s). Those students have already learned the importance of following the plans, and I help them wherever I need to however they need to be helped. Some will need lots of help, but many do not. I try to get them to do the Drill Point Gauge, the Scriber, and the BBQ Fork first, so that both Level 1’s and Level 2’s have three projects done for the first report card (mid-way through the course).

=======

Other tips:

I like to do a “song and dance” about something at the start of every class, if I’m not covering some theory unit. Sometimes I share stuff I’ve learned, sometimes I share something I’ve built, often it is a story that has nothing to do with Metal at all.

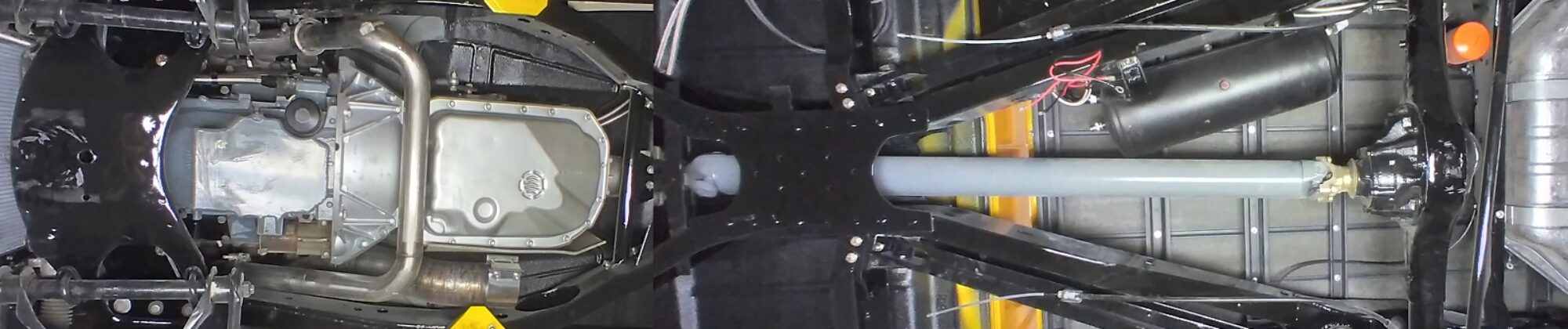

One brief song-and-dance I do is about bending tube, and different ways to bend it – especially useful for the Level 3’s who may be making gokarts or chopper bicycles. Bend (fold!) in a vice, bend around a pipe or wheel, bend with a conduit bender, bend with a tubing bender, and even sand-bent.

More to come, I’ve just lost my train of thought, and I have a class starting in ten minutes….