Return to the ’61 Apache

I have not found any tutorial on how to shorten these frame; most people either cut the X out completely, or swap to a 63+ frame. Another exciting bit of fun, is the frame rails taper under the cab, that is: they narrow at the front. While most people shorten the 63-72 frames under the cab, you cannot do that on the 60-62.

Some say that the 60-62 trucks have the best ride quality, and attribute it to the torsion bar front suspension. I would attribute the better ride quality to a significantly more rigid frame. Though I’m sure the torsion bars spreading the spring rate along the front third of the frame could be a contributing factor.

Undaunted, I have a Sawzall and a welder, and I’m not afraid to use them.

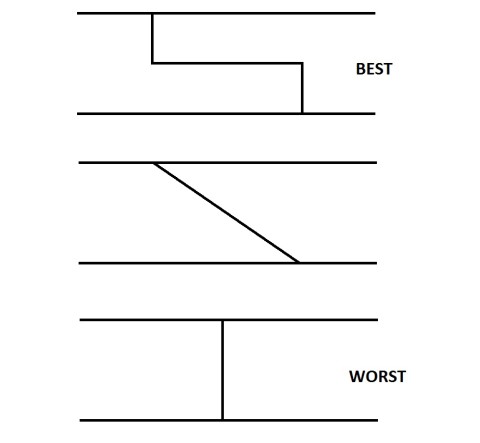

First of all, there are three kinds of cuts you can do on a frame:

Sadly, there really isn’t enough cut-able area to do the optimal Z cut – there is ONLY enough room to cut out ONLY the amount that needs to be gone. So, you’re stuck with the vertical cut, or a marginally angled cut. Just do straight cuts – with the extra legs of the X in the frame, it should be plenty strong. My current daily is a ’77 Squarebody with a vertical cuts and it’s been working fine (yes, I haul stuff with it).

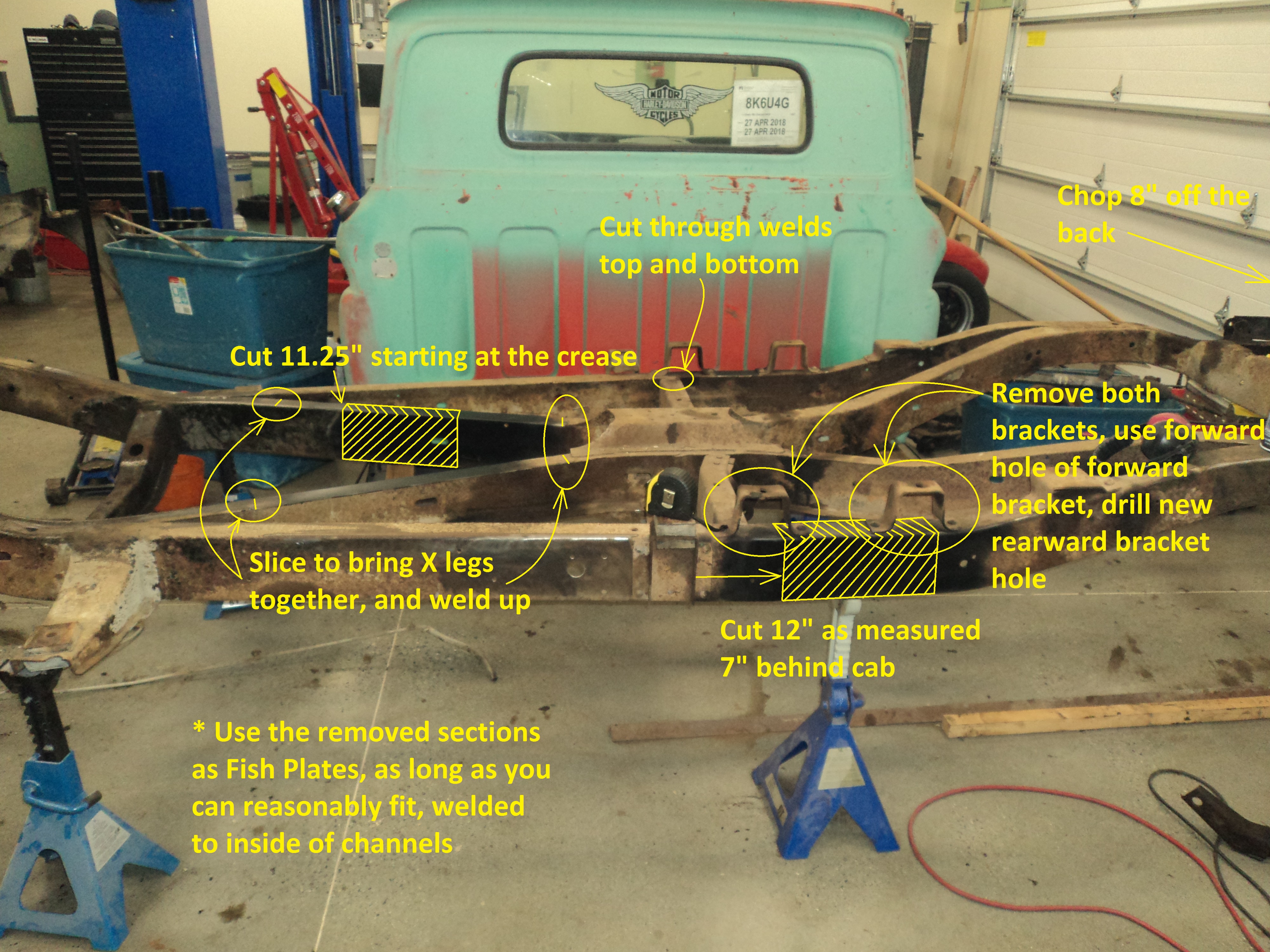

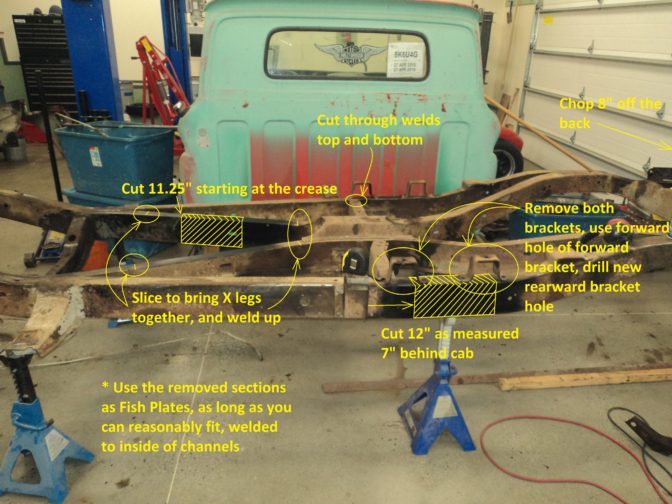

Knowing where to cut is key:

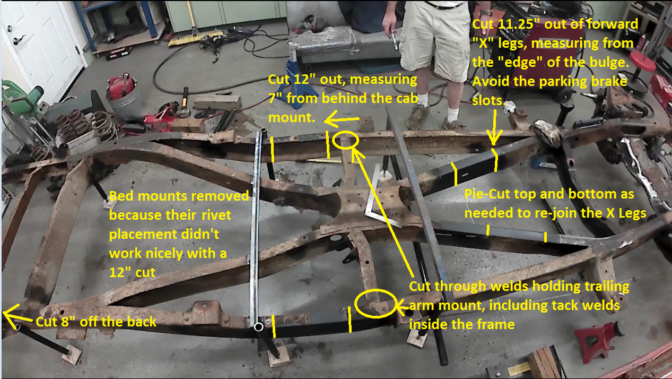

I welded eight legs to the frame with threaded feet so I could level the frame and then brace the snot out of it. I also removed the front four bed mounts, as the holes really weren’t going to work easily (you will need to drill two new holes for the front bed mounts).

Then I cut the sections out. I kept the sections to use them as fish plates.

I used ratchet straps and the gentle persuader to pull the two halves together. I also used ratchet straps to pull everything to square, and lots of clamps to hold it all true. This is where the legs with adjustable feet come into play again – since floors are never perfect, I had to re-level the frame halves as they sat in their new location. It didn’t need much correction, and the X is holding it in alignment very well. I got to +/- 1/32″ diagonals for squareness.

My frame appears to be a tick under 3/16″ thick, which is still really too much for my Lincoln 140 MIG welder. It -could- be done, but there is something to be said about a welder big enough to do the job properly.

I borrowed the Thermal Arc 210 Fabricator from work, which was awesome.

The forward legs of the X will have to be pie cut at the top and bottom to bend the leg sections back into alignment with each other. I tried to heat-shrink them with a torch, but it took forever to get nowhere. Just slice them and bend them.

I have a cheap eBay plasma cutter that has been working grand. Makes cutting the fishplates easy. I did the frame cutting with a cutting disc on an angle grinder.

The fish plates will need a bit of bending, because of the shapes of the frame where the cutting occurred. I used a hydraulic press to bend them. Clamp them in tight, and burn ’em in. I lifted the frame on edge just for easier position for welding, but do whatever you need to do to make it work.

Some say you should only fish plate the vertical welds and leave the top and bottom flanges alone. Others say you should fish plate all your welds. I’m not a welder. On my ’77 I did not fish plate the tops and bottoms of the rails, and it’s been sketching me out ever since. On this frame, I did tops and bottoms. Again, with the extra bracing the X provides, it will probably be fine either way. I’m also not an engineer.

You will need to trim the fish plates to avoid the e-brake slots.

I prefer to grind down only the welds that would be visible; don’t grind anything you don’t have to.

And done, once I add the front bed mounts (use existing front hole, drill new rear hole):

And, the whole she-bang in a video!

Return to the ’61 Apache