While I like to think I am very good at tuning a carburetor, and spent quite a bit of time fine-tuning the Rochester in the Crusty Chevy, and while it ~did~ run quite well, the 1970’s are over.

My greatest irritant was keeping a screwdriver in the truck so I could tweak the mixtures the teeniest bit every season. Just a little richer, just a little leaner. And every spring, when we were still burning the winter fuel but it was warm enough to vapour-lock, and with the headers: while driving….. Good times.

So, since I already had everything, I decided to finally do it. TBI first.

Day 1

I spend most of Day 1 changing the fuel lines and fuel pumps. The smart way to go about this, is to get a 1987 fuel tank, pickup, and pump. But this truck has dual tanks, and I (not thinking all the way through) had bought NOT 1987 tanks (no baffle) to the tune of $100 each when I first got the truck. This would mean buying two new tanks again ($200) and two EFI fuel pumps ($300). Instead, I used a low pressure pump I kept in the boot of The Lethal Locost when the cheap Facet pumps kept failing on me.

The tanks run to the switching valve, the switching valve goes to an AC Delco EP12S mounted at the lowest spot of the frame, which feeds a surge tank I fabricated out of aluminum. The surge tank stores fuel for a late 80’s Ford F-150 external pump, which in turn feeds the injectors. The injectors return to the surge tank, and the surge tank returns back to the switching valve and the appropriate tank. The purpose is so you never run the EFI pump dry. Makes perfect sense if you think about it.

Redneck butchery, eh?!

I picked up a fuel pressure regulator out of China, because it came complete with a gauge for $9, and I just needed the gauge. I will use the regulator on a later incarnation; the TBI unit has its own regulator built in.

I waste-cast an adapter base to fit the Q-jet intake at the foundry at school (I teach highschool metalwork, mechanics and drafting).

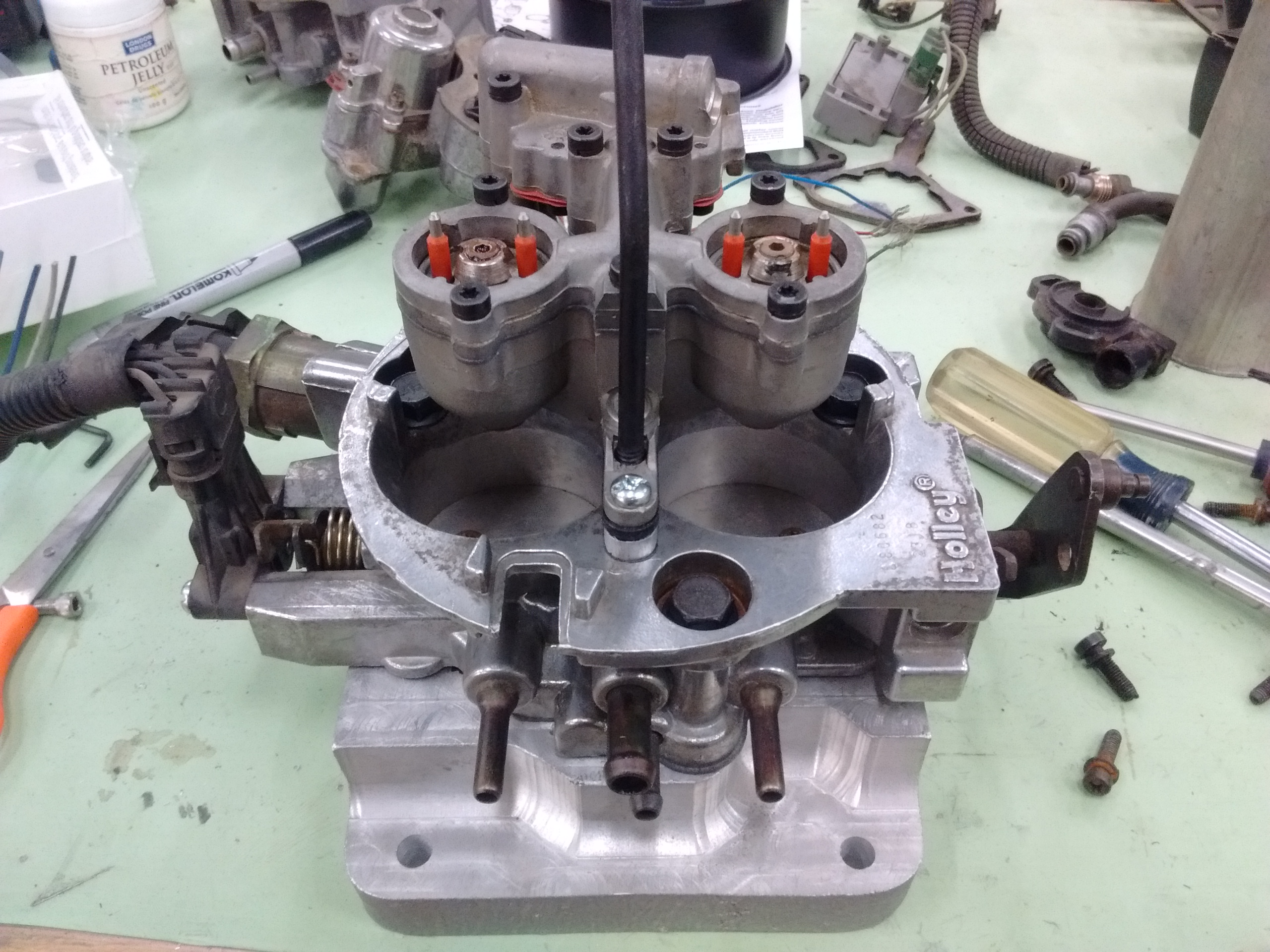

The TBI unit is a Holley big bore I picked up on Ebay, but discovered once I got it, that it had 4.3L V6 injectors. I modified a GM injector pod to fit the Holley base (since they aren’t really interchangeable), using a 1/4″ aluminum spacer I hand made with my wood scroll saw, breaking only two blades. The fuel regulator was modified to be externally adjustable.

I got the TBI unit mounted with no drama. I had forgotten to tap the back for the brake booster, but that didn’t take long.

I cut up a (presumably) TBI throttle bracket to fit the TBI where I had it, and still run the TH350. This was actually delightful, because this was the first time I used my sandblasting cabinet in the 13 years I’ve owned it.

Day 2

I finished up the fuel pumps and stuff on the frame, adding a filter after the EFI pump. Ran the lines up along the firewall, and connected to the pressure gauge and TBI unit. Pressure tested fine with no leaks, and set the regulator to 20psi.

This would have been a WHOLE LOT EASIER if I was willing to cough up the money for new tanks and two pumps. Stupid me.

Today was mostly wiring. The ECU got placed, all the sensors got wired, O2 bung got welded in but it shrank so I had to run into town in the Geriatric Buick to get an 18×1.5 tap. That will get threaded tomorrow, and the wideband will finally be installed.

The relay box is from a Nissan Pickup. It’s quite modular, so you can fit resistor packs, or relays, or what-have-you.

The bundled wires near it on the left are all for a heated O2. For now, I want to get it all tuned on the W/B, and then throw in a basic O2 for everyday driving.

I had to get a swivel-able thermostat housing, as the only temperature bung on this older Performer intake is pretty much under the hose itself. The hole is 1/2″ NPT, and the sensor is 3/8″ NPT. And no, the parts store didn’t have that adapter. Instead of wasting more time running around, I bought a 1/2″-1/4″ adapter that they did have, as well as a 3/8″ pipe tap, and made my own.

I tried to organize wires and make it all pretty like, but dang that’s work, and I pretty much need this truck up and running by Tuesday. If it all goes wrong, I can probably still throw the carb back on and drive it.

Day 3

I’m getting pretty sore folding myself into the engine bay all day.

Today I completed the wiring to the cooling fan (having MegaSquirt switch the fan relay), as well as get the wires ready to do the HEI-8 swap. For initial start, I wanted the old school original HEI in there – a “known good” quantity.

I had nicked an extra snorkel for the air filter, so I took the time to attach it. Looks mean!

I went to re-calibrate the wide-band O2 I nicked from The Lethal Locost, only to discover the sensor itself was dead. I matched the Bosch part number to a 2000-2009 Audi A4. I need to pick up another.

Once all the electrical and everything was done, I fired it up. It coughed, and chugged, and blew enough black smoke to set the smoke detector off in the shop, even with the 18′ door open. I opened up the barn fan and turned it on “expel.”

Once I got the VE bins sorted, and figured out the Idle Air Stepper Controller, it just ran inconsistent. Tach was everywhere, and none of it made sense. I suspect the VR signal.

As a test, I swapped in the TBI distributor I picked up at the wreckers (looked super good condition), but got less than nothing. No spark. I tested the pickup and module, and determined that the module was likely faulty. I pulled the known good distributor out of The V8 Firefly, and got it to pop once or twice, but only two sparks while cranking and then nothing. Not enough tach signal to the ECU to even keep the fuel pumps running.

So….

I put the Q-jet and HEI back on and drove it until another time.

Another time came soon.

I discovered something. Through the variety of inconsistent and confusing wiring diagrams for Megasquirt wiring, it seems I had not ~wired~ the VR input properly. I re-wired it, and lo and behold – it worked!

Now to calibrate and install the new Wideband O2 sensor, and start tuning!

Well. Figures.

For the most part, the truck drove fine. There was a strange herky-jerky that happened under medium throttle. The best I could figure by the end of today was the high pressure fuel pump was going out. However, full throttle pulls were ~not~bad~, but I didn’t get as many of those in. Whenever the herky-jerky happened, the AFR went WAY lean.

VERY driveable, otherwise. Light and part throttle was awesome. Smooth.

I figured maybe the herky-jerky was because I was using the large cap HEI and fuel only. So (again) I swapped in the HEI-8 small cap dizzy. Zero spark. Zero tach signal. I had followed some online re-wiring of the PCB for HEI, but nothing worked. I went back to the Megamanual PCB wiring instructions, nothing. I went through HEI diagnostics which condemned the module, but a new module didn’t work. I went back to the large cap HEI and it worked.

Drove nice, except the herky-jerky. I did a wack of tuning, got it really well sorted out. I ran a wack of errands, including picking up two loads of dirt for the yard. I stopped at a parts store on the way home and picked up a new fuel pump. Truck’s battery was dead. I got a jump, but no spark, no fuel pumps on, no tach signal to the ECU. I jumped the fuel pump relay and got pressure, but still no tach signal. Without my tools, I gave up and called the hook.

My shop isn’t easy to access with a towtruck, so I had it dropped on the street in front of my house. On the street I pulled the TBI off, and re-installed the Q-jet. I re-installed the mechanical pump off the motor, and fed it from a small Jerry Can under the hood to get it running and into the shop and on the lift, where I started pulling the rest of the Frankenstein fuel lines and pumps. I’ll finish that tomorrow.

All this EFI stuff is going into a box and left on a shelf until I can spend a much less stressful time of it. I need more success in the small windows of opportunity I have to muck with my daily like this.

I need a sticker on my dashboard to remind me: “Leave The Toaster Alone”

In other news, to deal with the dead battery issue (and always low voltage reading on the dash), I installed a new 94Amp 12SI alternator for an ’84 Camaro 305H.O. (bolts right in). Wow! The voltage gauge never read so high! And wow the truck ran well! And the signal light flash with authority! Impressive.

Dash gauge usually sat at 12-13V at idle, less if anything electrical was on. When the cooling fans were on (30A), the truck struggled to maintain 9-10V on the gauge. Add EFI to that, plus an inverter to run the lappy, then sit in traffic – no wonder the battery died.

For sale: used 10SI alternator from 1977 Chevy C10, low voltage edition.

Maybe the alternator was the cause of my issues……